Integrated AAV Offerings: From Cutting-Edge Products to Advanced Custom Services

Overcoming AAV Technology Challenges with Expertly Tailored Vector Design and Production

AAV Production Systems

One widely used method for producing AAV vectors involves co-transfecting HEK293 cells with three plasmids containing the necessary cis and trans components:

• AAV vector genome plasmid (pAAV): This plasmid contains the gene of interest (GOI) flanked by inverted terminal repeats (ITRs), which are the cis elements essential for AAV replication and packaging. The AAV vector plasmid serves as the template for the production of AAV vectors.

• AAV Rep-Cap plasmid (pRep-Cap): This plasmid carries the Rep and Cap genes, which encode the replication and capsid proteins of AAV, respectively. Rep78 and Rep52 are non-structural proteins encoded in the AAV genome necessary as trans elements for AAV production. The capsid proteins VP1, VP2, and VP3 play a crucial role in AAV capsid assembly and are therefore also required as trans elements.

• Ad helper plasmid (pHelper): The Ad helper plasmid contains the necessary adenoviral genes, such as E2a, E4orf6, and VA RNA, which are required to support AAV replication and packaging. The Ad helper plasmid provides the trans-acting factors necessary for efficient AAV vector production.

AAV vector production using the traditional transient transfection method have demonstrated safety, convenience, and effectiveness in clinical trials. However, this method has limited scalability potential. It is necessary to transfect all three plasmids into a cell, which limit the efficiency of AAV vector production. Transfecting multiple plasmids simultaneously can result in competition for cellular resources and introduce variability between production batches due to fluctuations in plasmid quality. Thus, optimizing the ratio of the three plasmids is crucial step for achieving higher AAV yields, especially for GMP grade AAV production.

Our partner, AAVnerGene has developed innovative technologies to improve AAV production. One of our key developments is the mini-pHelper, which is a smaller size plasmid (8.4kb) that provides Ad helper functions in triple-plasmid (AAVtriTM) system with higher package efficiency compared to other Ad Helper plasmids. Based on the mini-pHelper, AAVnerGene has developed a two-plasmid (AAVdualTM) and a single plasmid (AAVoneTM) system for AAV production.

Comparison of Production Systems

|

Production System

|

Plasmids

|

Plasmid Size

|

Total Size

|

Number of Plasmid(s)

|

Packaging Efficiency

|

|

AAVone

|

14-18 kb

|

14-18 kb

|

1

|

200%-400%

|

|

|

AAVdual

|

9.4-13.4 kb

|

17-21 kb

|

2

|

100%-250%

|

|

|

pRep-Cap

|

7.5 kb

|

||||

|

AAVtri

|

8.4 kb

|

21-25 kb

|

3

|

100%-250%

|

|

|

pRep-Cap

|

7.5 kb

|

||||

|

4-8 kb

|

|||||

|

Traditional Triple Plasmid

|

pHelper

|

11.6 kb

|

24-28 kb

|

3

|

100%

|

|

pRep-Cap

|

7.5 kb

|

||||

|

pAAV

|

4-8 kb

|

AAV Services

AAV Vector Design & Cloning

Expert consultation, design, gene synthesis, and cloning of custom AAV vectors tailored to your research needs.

Learn moreAAV Packaging Service

Reliable, affordable, and fully customizable AAV packaging service with diverse serotype options and high titer.

Learn moreAAV QC & Characterization

Comprehensive quality control assays including qPCR, SDS-PAGE, mass photometry, and next-generation sequencing.

Learn moreOther Viruses at Biohippo

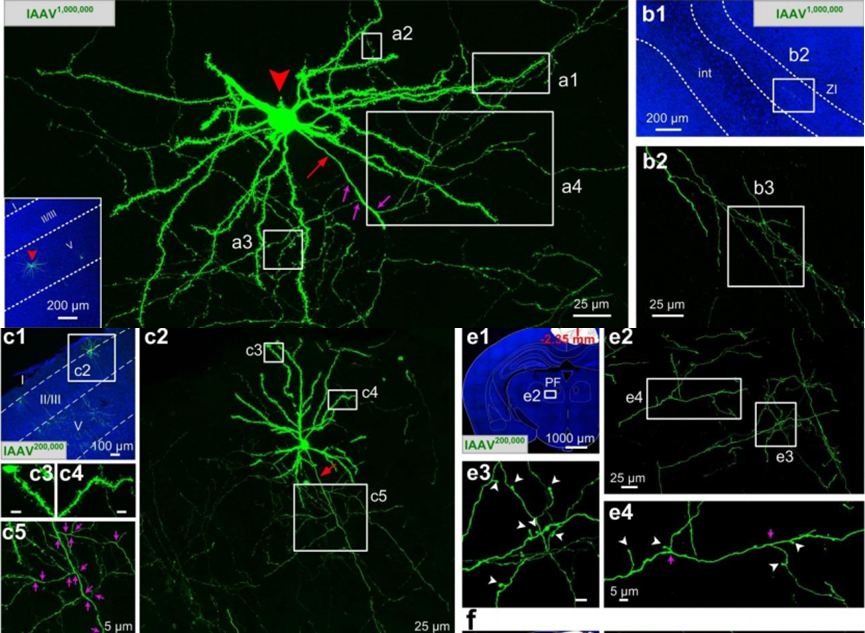

Neural Circuit Tracing

Biohippo offers a variety of viral vectors, including RV, HSV, PRV, and VSV, to replace conventional tracers with the highly efficient, more specific, and less invasive viral method.

Learn More

Lentivirus

Biohippo offers TF reporter lentivirus, immunotherapy lentivirus, validated shRNA, cDNA, and miRNA lentiviruses to meet diverse research needs. We also offer customized service at affodable price.

Learn More Loading ....

Loading ....